Kinshofer Group Germany

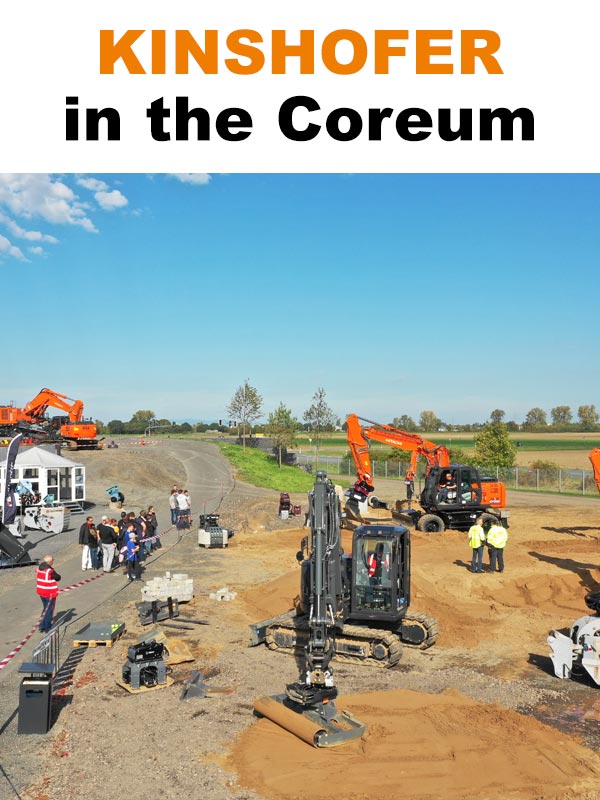

Welcome - KINSHOFER is a leading manufacturer of attachments for truck cranes and excavators for the most important industries worldwide.

From our headquarters in Holzkirchen, Bavaria, we offer our customers an extensive range of attachments for equipment carriers with or without hydraulics for scrap, demolition, track construction, landscaping, general construction, snow clearing, excavation, road construction, forestry, recycling, etc.

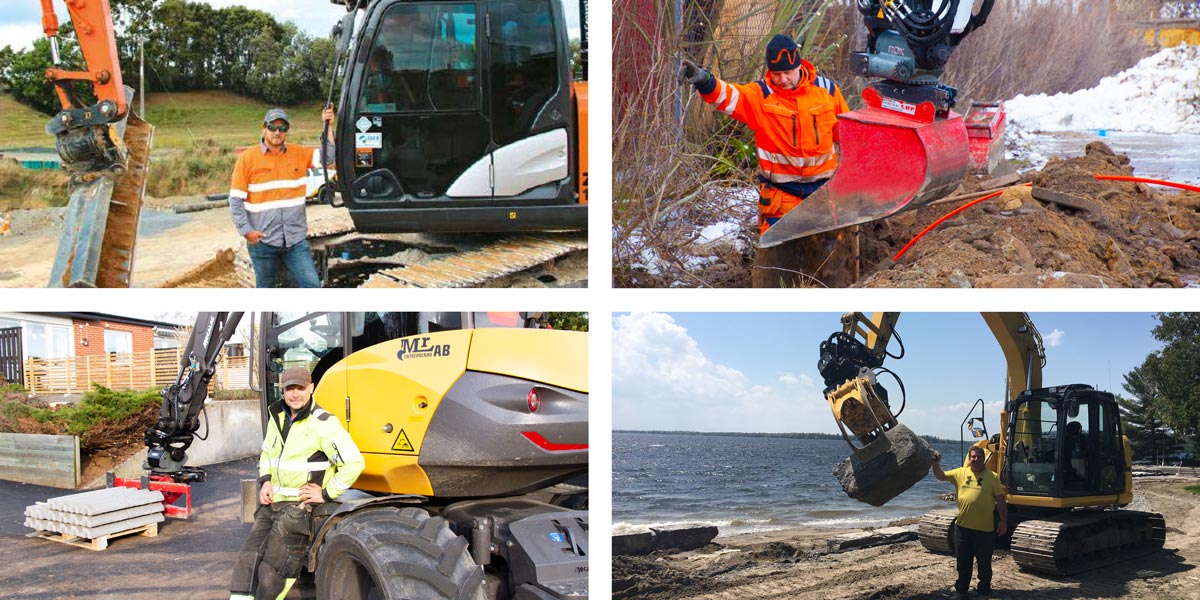

The continuing demand for transportation and infrastructure is constantly driving our product development and the service we offer. As a result, we are continuously expanding our product range in order to develop and produce technical highlights in the industries.

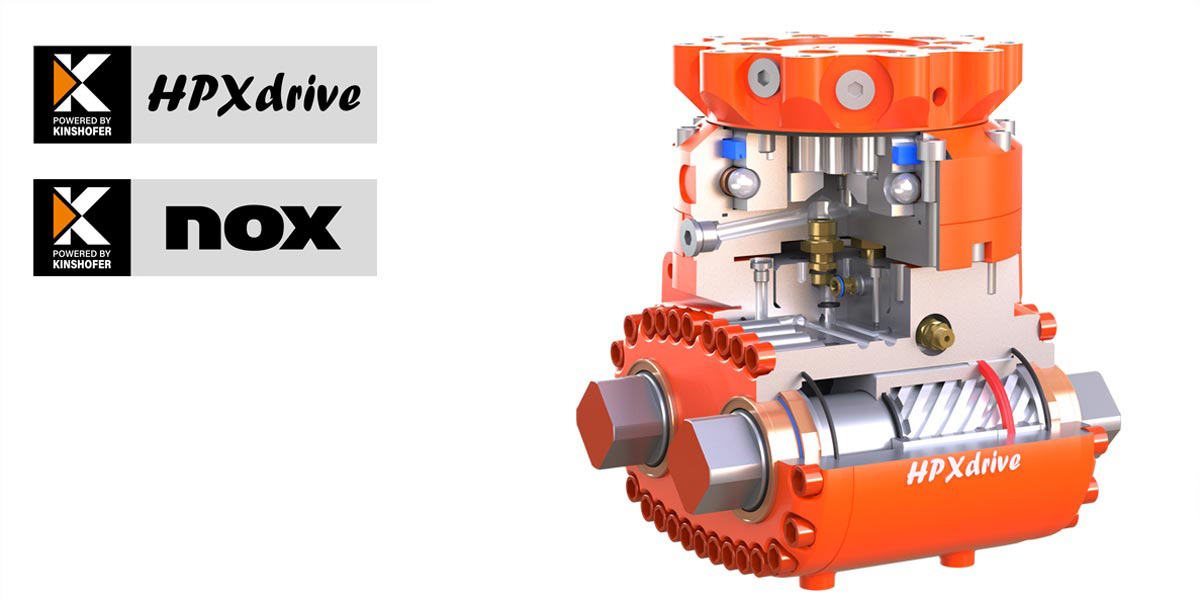

The cylinderless and low-maintenance technologies that are used for the HPXdrive on grapples or the NOX tiltrotators and TC tilt couplers are examples of these innovations, as are the products for special requirements or unusual uses from our special solutions department.

With high quality, variety and the latest technology, KINSHOFER crane and excavator attachments set standards worldwide.